The pandemic highlighted inefficiencies in the supply chain with labor challenges rising in its wake. Consumers expect more on-demand services, innovation, sustainability, and food safety. And although technology has been present in the industry for decades, digital transformation has upped the pace. Industry 4.0 technologies are enabling improved efficiencies across traditional food manufacturing processes. They can reduce manufacturing complexities, improve production quality and respond to regulations. So, what can we expect in the future? We examine in more detail what the future of food manufacturing could be…

Increased Use of Automation and Technology

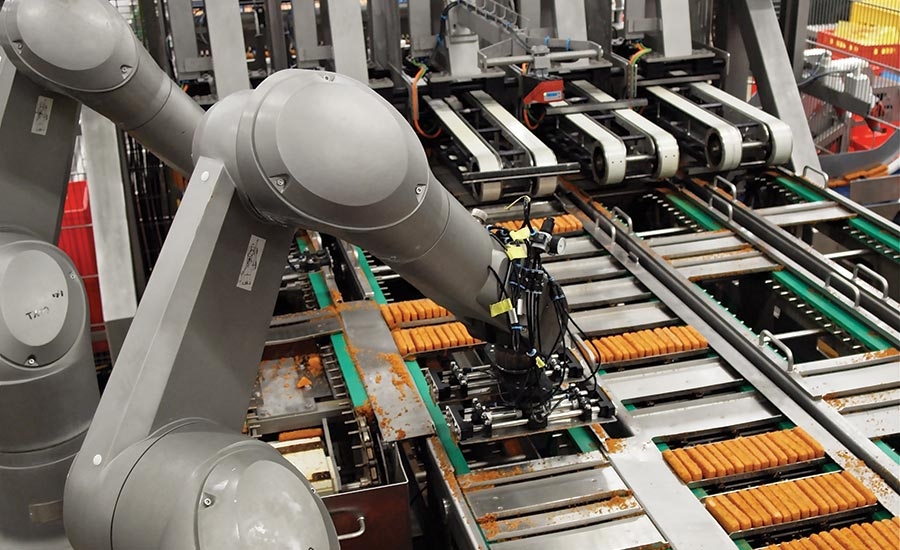

Choosing to automate some processes was an ‘option’ for manufacturers just five years ago. But in today’s market of sustained labor shortages and heavy competition, automation is becoming more of a necessity than a luxury to more fully meet consumer demands. Robotics, AGVs, and autonomous robots are becoming more prevalent in manufacturing – helping with efficiency and opening up more opportunities for workers to focus on value-added duties, overall creating a higher-skilled workforce. Automation in food packaging and palletizing is also likely to increase, for example, the use of food-handling robots in both primary and secondary packaging processes. The use of X-ray machines for detecting contaminants to improve quality standards, auto-sealers, and pallet wrappers for greater efficiency and accuracy has the potential to feature more too. Along with automation, new technology like blockchain is also helping manufacturers make their operations more efficient, provide improved transparency and potentially help them improve their food product design and engineering.

Food Safety Will Remain Paramount

In the aftermath of the pandemic, food safety has entered a new era, with a firmer approach adopted in all corners of the industry. Food manufacturers will look at new ways to protect the supply chain, and stricter regulations will ensure public health and greater food safety. An example of this is the recent recall of Romaine lettuce in the US, thought to be a possible cause of people falling ill. Data is likely to play a bigger role too. Regarding Food Safety Tech, FDA Deputy Commissioner Frank Yiannas said, ‘better food safety begins and ends with better data.’ This can help improve food recalls and provide more information on foodborne illnesses. Data related to product movement, performance, and the environment has the power to generate valuable trend insights driving improvements in food safety.

More Food Innovation

Manufacturers should also ready themselves for continued food innovation. We see this innovation already, with expectations further encouraged through social media, where consumers are exposed to new food products daily. Food processors who embrace new trends will help set themselves apart. Trends such as themed food, exotic and hot flavors, and nostalgic food are already proving popular. People also want to experience other cultures and the food that goes with them. Plus, although it’s been around for a while, plant-based meat looks like a trend that’s turning into a norm, with an estimated market worth of 4.1 billion. Expansion of this could spell the introduction of slaughter-free meat or, for example, cell-based sausages produced by companies like New Age Meats. Dishes like edible insect burgers may also feature in the future, along with new related food regulations. These preferences and interests are constantly changing, so manufacturers need to stay ahead of them and the related standards.

Increased focus on sustainability

Last but not least are the growing expectations in the food industry for greater sustainability. These expectations are present across all sectors and not just when it comes to food. Consumers today do their research and will investigate the sustainability efforts of companies involved in all areas of the supply chain. They want more sustainable food – according to a report in Forbes, 60% of consumers buy products and services from socially and/or environmentally responsible companies. This may affect manufacturers through the increased use and diversity of eco-labels on food packaging. For instance, according to a recent study, food shoppers could soon expect to see food’s environmental impact on labels before buying.

Conclusion

Nothing is a given in the food industry – an industry affected significantly by global trade, fluctuating consumer interests, worker shortages, and socio-political events. Although there is a degree of predictability related to these factors, there is no certainty. Food manufacturers need to find the balance between implementing new strategies that address these complex influences while also exploring and investing in the host of new technology and manufacturing processes available today.